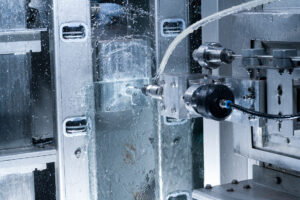

We invest in a fully automated systron proHD production line

Glass processing requires a lot of specialised skills. The demand for tempered, laminated and moulded glasses is constantly growing. Investing in state-of-the-art processing systems is therefore an important part of our ongoing, comprehensive development efforts. Our latest investment, the systron proHD glass processing centre, enables glass pre-processing with a single system. CNC-ground and polished external and internal shapes, as well as waterjet drilling and cutting, can be done with the same positioning. With our new production line, both individual glasses and series production glasses can be made cost-effectively: machine time and costs are always known. The production line will be operational in June 2023 and will feature:

– Fully automatic production line with patented CNC and water cutting in one machine

– All glass machining in a single positioning

– Flexible for individual and serial production glasses

As energy and material prices rise, the use of more efficient systems is also important to maintain our competitiveness. Our new production line can be used for unmanned production, for example for the night shift, when energy costs are lowest. In addition, the vertical machine achieves maximum flexibility and yield in the smallest possible production area.

The use of robots is part of the flat glass industry. Advanced robotics and automation will help keep jobs and downstream processing in Finland. Development work is essential. From the outset, the factory’s facilities have been designed to serve the smoothest possible downstream glass processing operations.

For most of those who have visited Lasiliiri’s production facilities, the factory has left a positive impression, both in terms of the size of the operation and its efficiency. Welcome to visit.