SaniTise ™ Antimicrobial glass

Pilkington SaniTise ™

Pilkington SaniTise ™ is an on-line coated glass with a transparent photocatalytic coating that gives the surface antimicrobial properties and activity against enveloped viruses when exposed to UV light.

The coating retains its properties, reducing the risk of infection in a tested manner for up to two hours, even if UV exposure ceases.

Properties and benefits of antimicrobial glass

● Pilkington SaniTise ™ is a high quality photocatalytic

coated glass that can be used in a variety of applications

in various glazing applications

● Pilkington SaniTise is highly resistant to corrosion,

against mechanical forces and chemical damage

● Pilkington SaniTise ™ can be activated by sunlight or

with artificial UV light. It can be activated quickly

254nm light wavelength, which is also used

UV disinfection in systems

● Pilkington SaniTise ™ quickly reaches full power

after exposure to UV light – only 5-10 minutes of exposure is sufficient;

● Pilkington SaniTise ™ can double UV disinfection

effect

● Once activated, Pilkington SaniTise ™ retains its photocatalytic

functionality for up to two hours even in the dark;

● When activated, Pilkington SaniTise ™ is also oleophobic

(e.g. anti-fingerprint) and easier to clean than

regular glass

● The product can be hardened, laminated, bent and processed

into an insulating glass element.

Indoor applications

● wall glazing

● protective glass, glass railings and partitions

● table tops and countertops

● splash guards

● furniture

● Freezers and refrigeration appliances

● Protective glass for touch screens

Action of antimicrobial glass

The glass utilizes a TIO2 – based coating, which is

applied directly to the glass surface during the glass manufacturing process.

When Pilkington SaniTise ™ coating is exposed to natural UV light

or for light produced by UV disinfection equipment, it is activated.

The coating then reacts with the water vapor in the air

forming a photocatalytic reaction which produces reactive

oxygen compounds. These compounds allow for many

activities, including the decomposition of organic compounds,

antimicrobial properties and activity of enveloped viruses

against the surface of the glass.

When coated glass is treated using a UV disinfection process, the disinfection efficiency is even doubled compared to uncoated glass.

(Source: Pilkington)

ANTIMICROBIAL GLASS SURFACES WITH PHOTOCATALYTIC COATING

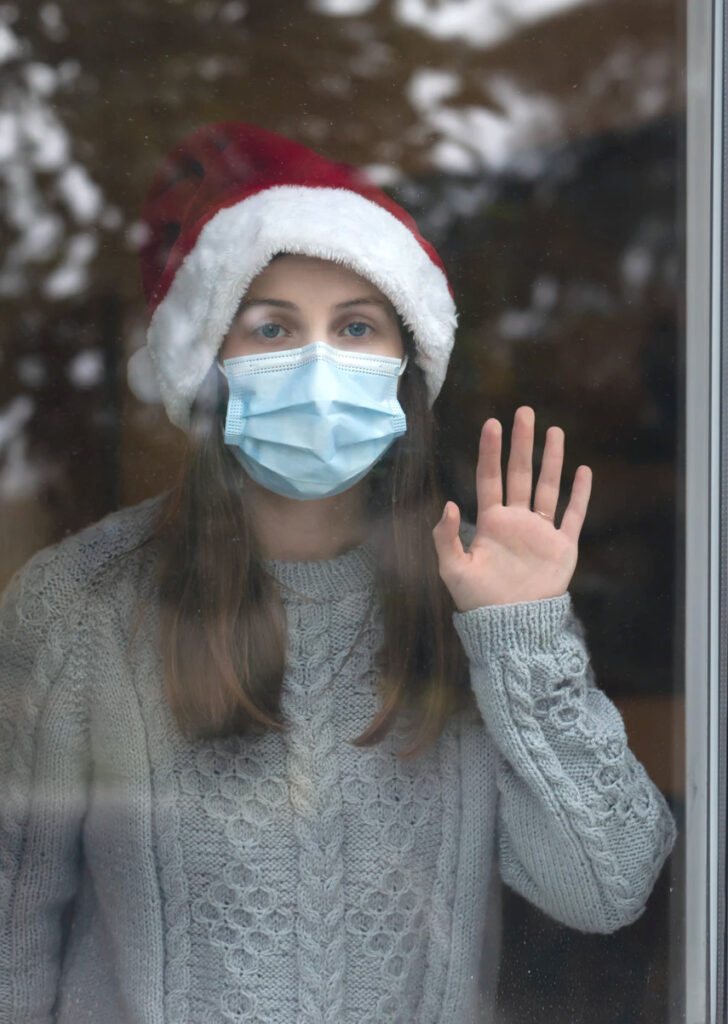

Antimicrobial glass surfaces are perfect for public spaces

and window surfaces of installations where modern level of hygiene

is required. Antimicrobiality can be seen to be a part of

the features of modern safety glass. Glass antimicrobial

glass solutions are suitable e.g. safety glass, interior and exterior windows,

sliding glass, revolving glass, mirrors, room dividers,

glass railings and glass for partition systems. Architects

and designers have received coated, antimicrobial glass

with great interest.

New, antimicrobial protection is just as important

than the physical protection provided by traditional safety glass

Antimicrobial glass surfaces will help fight the Covid 19 pandemic as well as possible future pandemics. Antimicrobials also provide protection against the spread of flu infections.

Due to antimicrobiality, the concept of traditional safety glass is getting an update. Although the glass surfaces are made antibacterial, they can still be tempered and laminated at the Riihimäki plant as heat and sound insulating glass and safety glass. In addition, image and graphics can be added to antimicrobial glasses with Print Glass technology, and the glasses can be machined for many different shapes and uses.

Antimicrobial glass can be made into smart DIM Glass

Antimicrobial glass surfaces are ideal for DIM Glass smart windows. When glass walls, room dividers and door glass are equipped with the intelligent DIM Glass feature, opaque glass is made to become completely transparent in a tenth of a second.

The switch can be controlled e.g. with a timer, motion sensor, touch switch, remote control or even a mobile phone. In the opaque sleep mode, the tempered and laminated glass solution can be white, gray, black, or it can look like etched glass. When a low voltage is applied to the glass, it instantly becomes transparent. The most popular uses for DIM Glass are hospital operating rooms and control rooms and office meeting rooms. Lasiliiri’s customers use the solution in a very versatile way, e.g. in windows, doors and glass walls.

MICROBE PROTECTION IS PART OF THE OPERATION OF MODERN SAFETY GLASS

The threat of pandemics has been seen to increase in recent years. Antimicrobial glass surfaces are perfect for window surfaces in public spaces and institutions that require a modern level of hygiene. Antimicrobiality can be seen as part of the properties of modern safety glass.